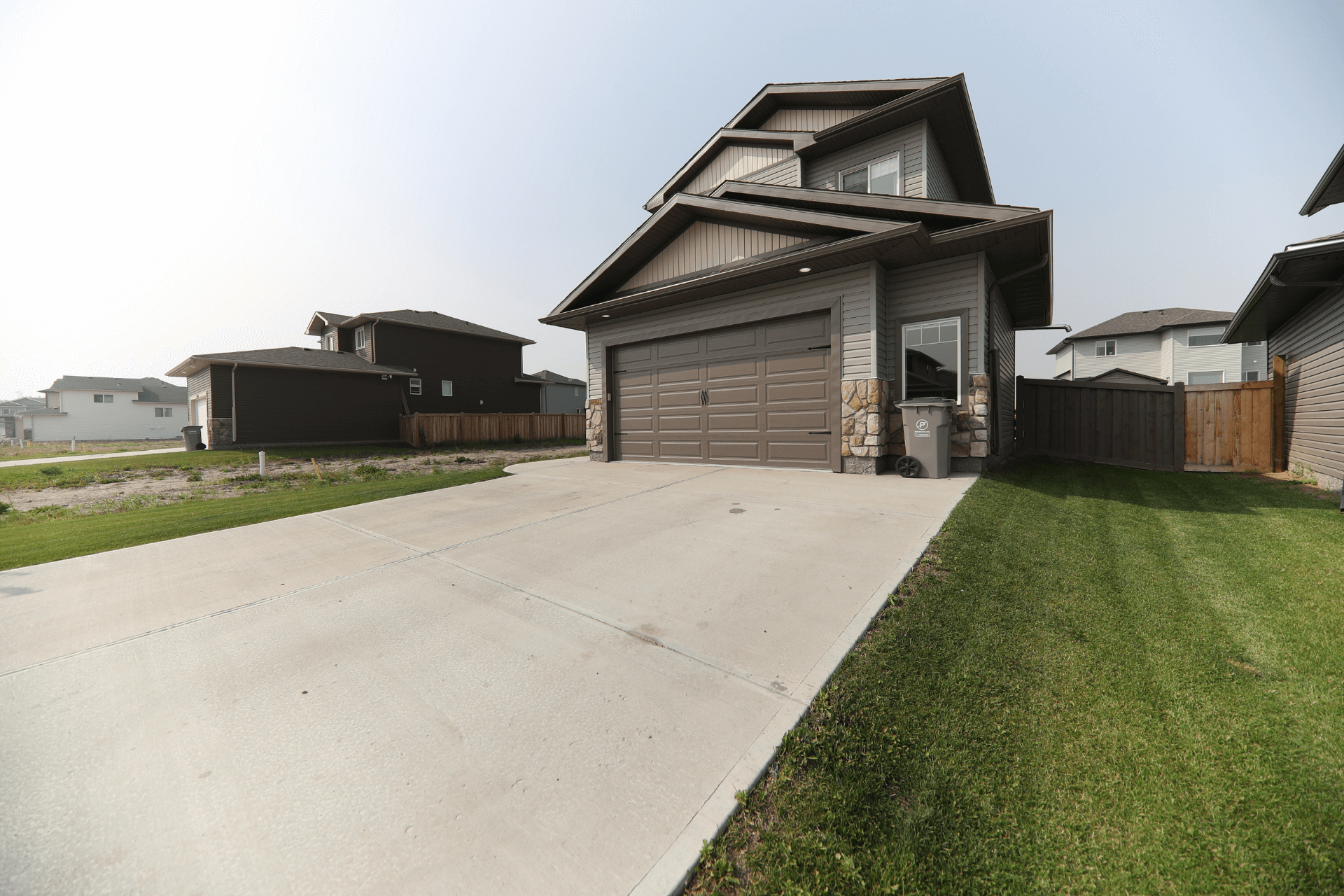

CONCRETE DRIVEWAYS

Concrete is an ideal plain material for driveway construction. Most people favor it because of its durable and robust features. Moreover, a concrete driveway requires very little maintenance.

A concrete driveway made by our expert concrete contractors will have unparalleled longevity. We use good quality concrete to cover large areas of paving.

A concrete driveway can outlast an asphalt one because of its longevity.

We can color plain gray concrete to eliminate any dull appearance. Therefore, making your concrete paving surface in the exterior of your home, unique and attractive with stamping or coloring. With Nashville Concrete Experts, your driveway will be decorative and stand out in the neighborhood.

What Are Concrete Driveways?

A concrete driveway entrance is low-maintenance and visually attractive, but several parts to the installation process are considered. The right design, the weather, the thickness, the budget, the design, how to prevent cracks, and more are important areas for homeowners to consider when choosing to install a concrete driveway.

It can also play a factor in deciding with a contractor to help you have a better and beautiful concrete driveway.

Concrete Mix

The type of concrete mix used benefits and makes a large impact on the durability and strength of your new driveway project. One of the best kinds of mixes is air-entrained, meaning that air is added into the concrete mix pour to create plain bubbles.

This is performed to prevent the appearance of cracks from forming in colder weather. Cycles of cold weather can freeze, thaw, and crack concrete driveways, causing more performance damage over time.

When there are air bubbles present, then there is less pressure, so the concrete won't crack as much. Also, look for those that generally use a cement one that has a lower water ratio. The less water, the more durable the cement and gravel becomes, thus fewer cracks will form, hence preventing driveways' surface from cracking.

Concrete Joints

Concrete joints are just intended cracks that you want in your driveway style. If you live in a colder region, then it is important to have joints to help prevent cracks in your driveway. Different types of tools are used to form the joints depending on the weather.

In colder areas, grooving tools would be used on the fresh exterior of concrete, and in hotter weather, a saw can be used 6-12 hours after finishing. There are many patterns for a homeowner to discover and choose from.

A professional contractor should advise you on which designs, style, and gravel are suitable for your situation and to your liking as well.

Bleed Water

A concern when a driveway is being finished is bleed water. This is when the water from the mix rises to the top. This can ruin the finish and cause staining. There are many tools that are used to finish.

A screed is generally used to level the concrete material, and a bull float is used to prevent bleed water from occurring. Finally, the driveway or paving can be stamped on the surface with a design or swept with a broom to create traction. A stain can be added afterward.

The last step of the process is to cure the concrete to help your driveway become durable. To do this, either a plastic sheet or a curing blanket is used to cover the entire driveway after adding a curing compound solution. A decorative membrane forms on the surface of the driveway, which helps it hold up against hot and cold weather conditions.

Maintaining A Concrete Driveway

Concrete driveways require light to no maintenance or repair. However, to ensure a long life, you need to keep it clean. We perfectly craft our concrete driveway to withstand traffic from heavy vehicles.

You can keep it better maintained using a hose for a good scrubbing. Further, we advise you to use a stiff brush to handle the best cleaning on your concrete driveway designs. Moreover, we add a concrete sealer to bring an extra layer of protection to your driveway.

Every year you need to renew the sealer to get rid of erosion. With natural changes and the presence of brick road salts, it is best to apply a sealer stamp on the border at least once a year. Sealing will keep your concrete driveway from getting damaged, and it will serve its purpose.

There are also methods to reinforce your concrete driveway designs if you know that you will have high traffic on your driveway. Steel can be used to ensure that current cracks do not get worse on your driveway, but they cannot prevent cracks on the material from forming. Homeowners can also use wire mesh materials on a driveway to reduce any extra cost.

Why Get A Concrete Driveway?

The service life of a concrete driveway is 50-60 percent longer than an asphalt driveway. Therefore, our driveway will save you money and cost. It has a low-maintenance feature that will perfectly suit your driveway needs.

With a concrete driveway, your property appeal will increase. There are creative design ideas and decorative surface colors available from which you can choose your favorite. Moreover, stamped concrete surfaces have a texture that will please you and give your driveway a gray or better natural look.

The stamped concrete will blend with your property design. Further, it will give your home concrete a highly textured and stamped look. Concrete driveways reflect heat and make the paving surface cooler. Moreover, it absorbs less radiation that makes it suitable to walk barefoot.

Further, these driveways do not require much lighting and will save you energy over the years.

Our concrete driveways are rigid, therefore, able to handle heavy vehicles. This non-flexible material can withstand the traction of larger trucks.

You can reduce the maintenance cost by using contraction joints and sealers. It will increase the longevity of your driveway. Therefore, you can be free of worry after installing and sealing your new driveway.

These driveways are environmentally friendly as it saves energy costs. Our concrete paving contractors will ensure a smooth and effective installation process.

If you ever want to sell your house, the installed concrete pavement or decorative driveway will factor into increasing the appeal. This pavement will increase your resale value.

Types Of Concrete Driveways

Here are the different types of concrete driveway design ideas and services that we can create for increased performance and better curb appeal:

- Jointed unreinforced concrete pavement

- Continuously reinforced concrete pavement

- Jointed reinforced concrete pavement

- Roller compacted concrete pavement

- Concrete overlays

- Pre-cast concrete pavement

A concrete pavement surface is a durable and effective way to enhance the appeal of your home. Do you want concrete pavement installed or have any driveway-related issues on your Nashville property? You can reach out to Nashville Concrete Experts for ideas for driveways. With the help of our professional Nashville concrete contractor, we will build the perfect concrete driveway ideas for your entrance that are immune to cracking and increases your curb appeal.

Request a quote

Santa Clarity Concrete Expert Leads

There are also methods to reinforce your driveway if you know that you will have high traffic on your driveway. Steel can be used to ensure that current cracks do not get worse, but they cannot prevent cracks from forming. Wire mesh can also be used.

A concern when a driveway is being finished is bleed water. This is when the water from the mix rises to the top. This can ruin the finish. There are many tools that are used to finish. A screed is used to level the concrete and a bull float is used to prevent bleed water from occurring. Finally, the driveway can be stamped with a design or swept with a broom to create traction. A stain can be added afterward.

The last step of the process is to cure the concrete to help your driveway come durable. To do this, either a plastic sheet or a curing blanket is used to cover the entire driveway after adding a curing compound solution. A membrane forms on top of the driveway which helps it hold up against weather conditions.